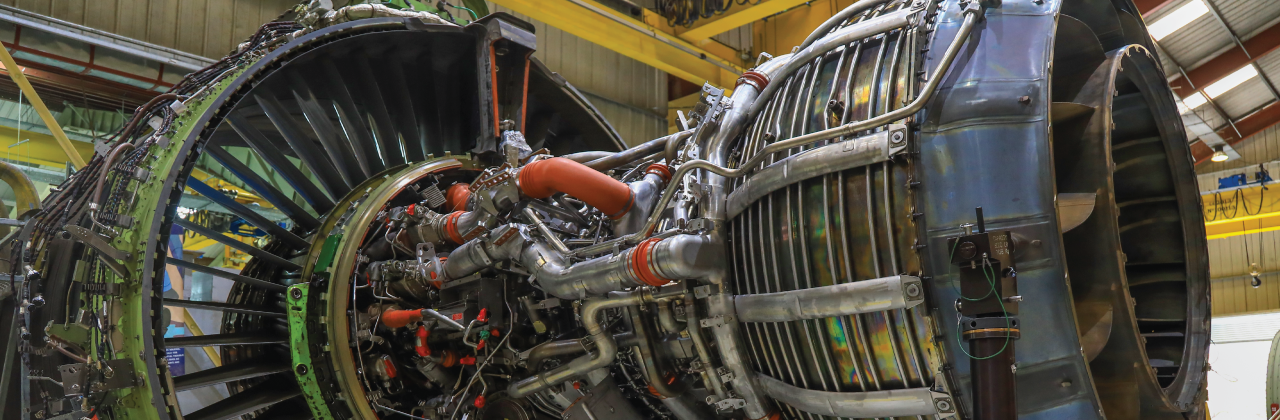

The Engine shop has over 55 years of experience in engine maintenance and it has been working with many airlines, engine lessors and other customers. Placed on 12,000 Sq. m, the shop is equipped with state of art machines and tools to deliver services to our customers from all over the world.

Engine maintenance

Complete repair, modification, overhaul and testing of:

Modular maintenance

Split and Rebuild

On-site support

CFM56-7B

GE90/GEnx

Engine teardown

We provide complete engine teardown for CFM56-7B

Test cell

In support of its engine overhaul facility, Ethiopian utilizes a fully equipped jet engine test stand and a two-cell modern turboprop engine test bed. The 100,000 lb thrust test cell - a capacity significantly above the current power level for wide-bodied aircraft - provides a safe environment in which to fully test overhauled engines.

Our test cell can test the following engines:

Repairs

A range of special process shops equipped with state of art machines have capabilities such as: